Participating in the Carbopath™ Platform

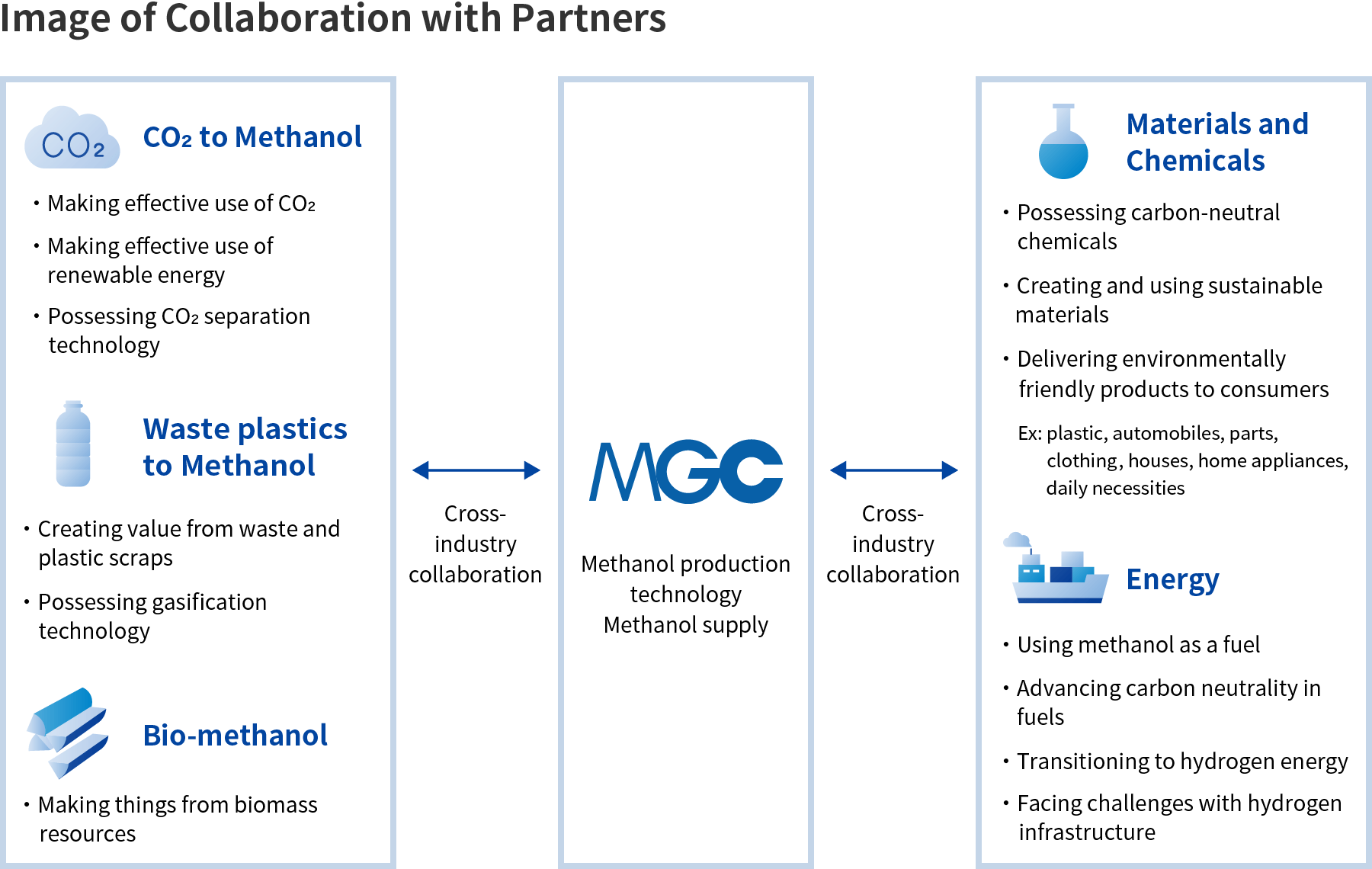

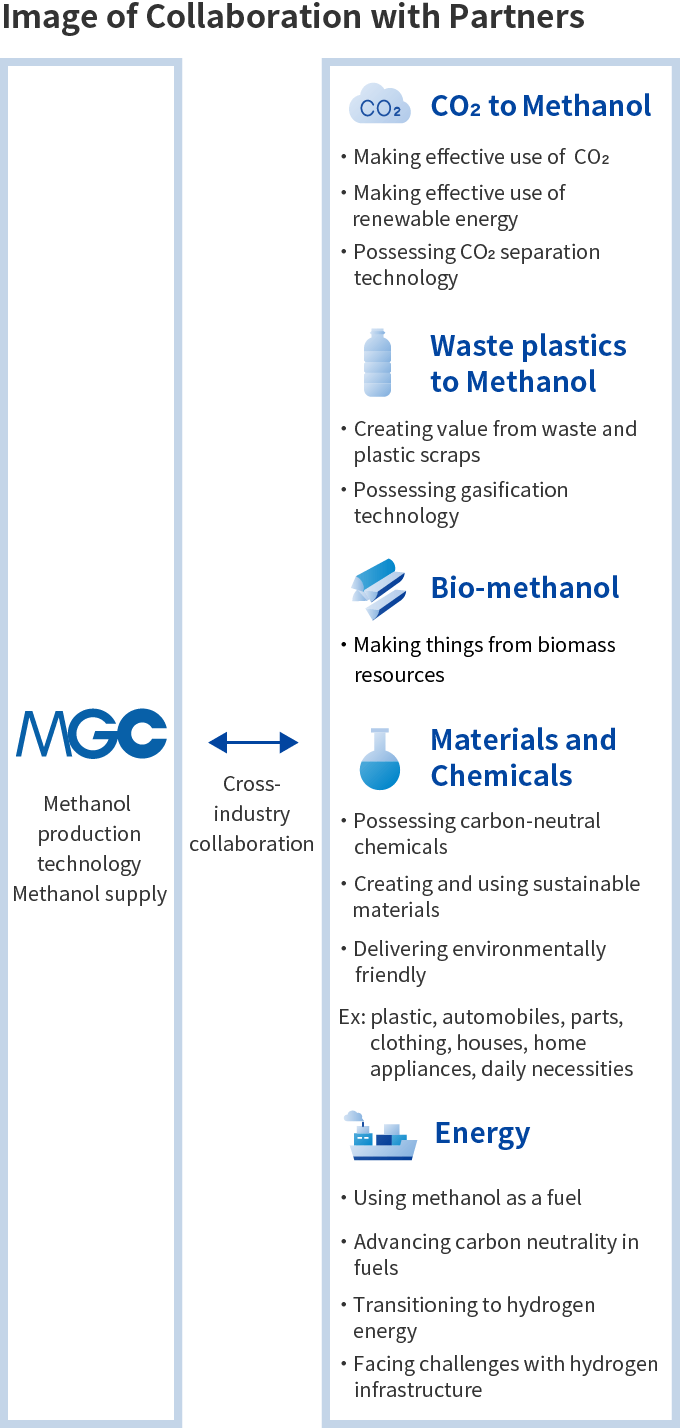

The Carbopath™ platform for a more recycling-oriented world is open to participation by local governments, companies, organizations and individuals. Increased participation in Carbopath™, which uses MGC's proprietary technology to produce green methanol from CO₂, waste plastic and biomass, will further accelerate methanol-based carbon recycling and thereby contribute to carbon neutrality.

- ・CO₂, plastic waste and biomass can be effectively used to create value and reduce CO₂ emissions.

- ・Methanol is already used in diverse products, so Carbopath™ can help make these products greener, reduce CO₂ emissions and create environmental value.

- ・Our initiative supports carbon neutrality through across-the-board collaboration, from renewable feedstocks, CO₂ capture and gasification technology to end products.

- ・In addition to producing methanol as new fuels, we are also supporting its safe use and building a reliable framework in collaboration with partners.

- ・To further expand the use of methanol in new materials, we are working with value chain members to build supply chains, create new value, and produce green products as well as promote their use in global society.

- ・The supply of green methanol is underway, so we can support your sustainability activities as a carbon-neutral, ready-to-go initiative.

- ・As CO₂ and waste use become increasingly important issues in various industry, our operational expertise in digital transformation (DX) can help companies produce methanol even if they have little experience in chemical manufacturing.

Key Projects

First company to produce bio-methanol from digester gas in Japan

In June 2024, MGC began producing bio-methanol from digester gas for the first time in Japan at its Niigata Plant. The gas is supplied to MGC from a sewage treatment plant in Niigata Prefecture, and MGC produces bio-methanol as a fuel and as a feedstock for chemicals. Both the digester gas and the bio-methanol are certified as sustainable products under the ISCC PLUS scheme.

Methanol Bunkering Simulation Conducted in Port of Yokohama

In September 2024, MGC participated in a bunkering simulation in which the Eika Maru transport vessel supplied methanol to the Alette Maersk container ship, which uses methanol as a marine fuel. The simulation was a major step toward establishing a supply system for methanol-fueled ships, an initiative aimed at decarbonizing the shipping industry. MGC, Yokohama City, Maersk AS and six other parties joined the simulation.

Japan’s first successful methanol production from municipal solid waste

In March 2022, JFE Engineering Corporation and MGC demonstrated the Carbon Dioxide Capture and Utilization (CCU) process by converting CO2 into methanol using exhaust gas recovered from a waste-to-energy plant, a first in Japan.

Circular carbon methanol using CO₂ during glass production

In August 2023, AGC Inc. and MGC agreed to study the use of MGC’s technology to produce methanol from CO2 generated by AGC during the production of architectural glass, aiming to launch the world’s first commercial production of circular carbon methanol from glass at AGC’s Kashima Plant by around 2030.